Indispensable in production - drill bushes for your machining operations

Advantages of drill bushes

Special solutions for special requirements - our range

Drill bushes from norelem

Indispensable in production - drill bushes for your machining operations

Drill bushes are mechanical components that are used in machines to precisely guide drills. They enable fast drilling of workpieces. Drill bushes eliminate the need to repeatedly measure and mark out. These standard parts guide the drill in a drilling jig. They not only guarantee a precisely bored drilling pattern, but also ensure that the drill bit does not drift. This is crucial for the accuracy and repeatability of bores, especially in series production.

In contrast to drilling without a jig - hand-guided drilling - the drilling process is significantly simplified by using these drill guides. Drilling using a drill bush achieves a much cleaner result by specifying a fixed penetration angle.

Drill bushes are made of special low carbon, case-hardened steel to ensure high wear resistance. As a result, they fulfil high quality standards and are also particularly durable. They are available in various shapes and sizes to meet differing requirements.

Drill bushes are widely used in machining, especially in areas where the precision and repeatability of bores are crucial. As they significantly improve the efficiency of the production processes, utilising these parts is essential.

The bushes are primarily used for deep drilling in machine construction. They are also used in tool making, vehicle construction and various other branches of industry. Our drill bushes are designed for harsh environments and to give a long service life.

Advantages of drill bushes

Drill bushes offer a number of advantages that not only make the drilling process more precise, but also more efficient and durable. The advantages make drill bushes an indispensable tool for precise and efficient drilling in industrial manufacturing.

Wide range: The range offers a comprehensive selection of seven different products. This enables you to select the optimum diameter, the appropriate material and the desired design to meet your specific requirements. This diversity ensures that the perfect drill bush is available for almost every application.

Long service life: The use of high quality steels such as free-cutting steel and case-hardened steel means that the drill bushes are exceptionally durable. These robust materials ensure high wear resistance and a long service life, which leads to a reduction in maintenance and spare parts costs in the long term.

Simple integration and exchangeability: Drill bushes can be easily integrated into existing systems, making them particularly easy to handle and replace. This means that they can be quickly and efficiently installed in production lines or replaced if necessary without the need for extensive modifications.

High precision: The exact drill guidance ensures that holes are always drilled precisely and in the correct position. This high precision is crucial for maintaining tight tolerances and the quality of the finished products.

Consistant repeatability: The consistent quality of the bores in every application makes drill bushes particularly valuable in series production, where identical results are crucial.

Increased safety: The use of high-quality materials and the stable drill guidance minimises the risk of tool breakage or drilling errors, which increases work safety.

Rapid drilling: Drill bushes enable quick and smooth drilling due to the precise guidance of the drill bit. There is no danger of the drill point wandering, which speeds up the entire drilling process and increases productivity.

Common standard parts system: Drill bushes are part of a uniform standard parts system, which simplifies their compatibility and integration into existing systems. This not only facilitates replacement, but also procurement and maintenance. Our bushes are manufactured to meet DIN standards.

In addition to the advantages listed above, the avoidance of drill drift and the simplification of the drilling process are also major benefits of drill bushes.

Special solutions for special requirements - our range

The norelem range includes seven different products to meet a wide variety of requirements. The range of sizes and variety of styles means that they can be precisely adapted to your existing system. The bushes are available in Form A and Form B. By Form A only one end is rounded, Form B is rounded at both ends. Each of the seven products fulfils the relevant DIN standard, depending on the type. The DIN standards define uniform specifications, requirements and provisions for products to ensure quality, safety and compatibility. The following DIN standards are observed depending on the product:

DIN 172

DIN 173

DIN 179

DIN 9845

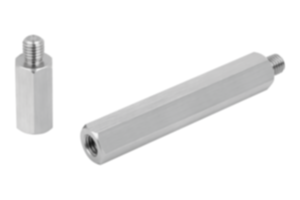

Cylindrical drill bushes DIN 179

DIN 179 cylindrical drill bushes are standard guide elements. The are built into drilling jigs to precisely guide the drill. The cylindrical bushes are made from a special low carbon steel which is hardened and ground.

DIN 179 specifies the exact dimensions and tolerances for these drill bushes to ensure that they can be universally deployed in various devices and applications. This standard also defines the fit, which ensures reliable and precise guidance of the drill bit. |

Cylindrical drill bushes are also often used as positioning bushes. The bush can be pressed in flush and combined with DIN 173 push-in bushes.

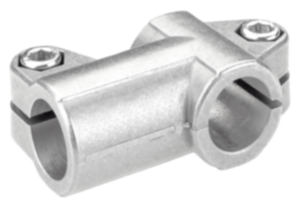

Flanged drill bushes DIN 172

DIN 172 flanged drill bushes are characterised by a collar that enables secure positioning in the fixture and prevents the bush from slipping out during the drilling process.

The flanged drill bushes are manufactured from high-quality special case-hardening steel, which is known for its high strength and durability. These standard parts are hardened to 740 ±80 HV 10, which gives them high wear resistance. They are also precision ground to ensure exact guidance of the drill bit.

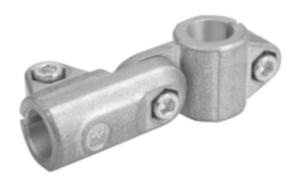

Push-in drill bushes DIN 173

DIN 173 push-in drill bushes are made of high-quality special case-hardening steel. They have no lead-in groove, which makes them particularly suitable for applications where smooth and even guidance of the drill bit is required.

In comparison to cylindrical drill bushes, push-in drill bushes are marked with the drilling dimension on the top flange face. The marking makes it easier to identify and quickly replace the bushes during production. This means that different diameters can be realised in a shorter time.

Matching products for the push-in drill bushes are:

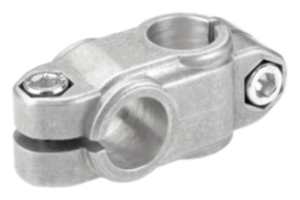

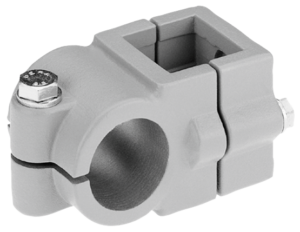

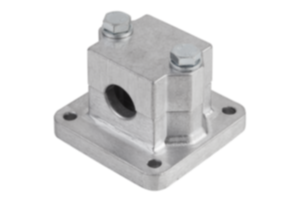

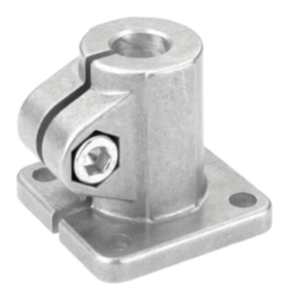

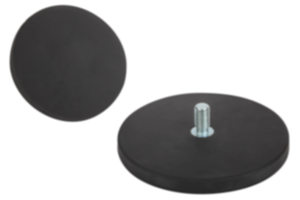

Drill bush clamps DIN 173

DIN 173 drill bush clamps are special fastening elements that are used in various industrial applications. These standard parts securely fixate DIN 173 push-in drill bushes or similar components in the fixture. They ensure a firm and precise connection and facilitate the replacement of drill bushes.

DIN 173 is a standard that covers push-in drill bushes and their properties as well as their use in industrial applications. The standard defines various aspects such as dimensions, tolerances, material requirements and designs to ensure that these bushes can be used precisely and reliably in drilling jigs.

The drill bush clamps are supplied with a DIN 912 cap screw, which is used to fasten the clamp. The combination of clamp and bush ensures simple and reliable installation.

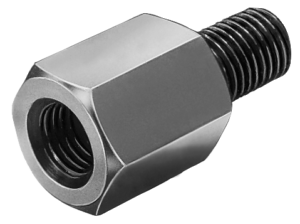

Flathead shoulder screws for DIN 173 push-in drill bushs

Bright steel flathead shoulder screws are designed for use with DIN 173 push-in drill bushes of various diameters. The diameters are categorised as follows:

up to 6 mm

over 6 mm to 12 mm

over 12 mm to 30 mm

Punch guide bushes DIN 9845

DIN 9845 punch guide bushes are used in machine tools and punching machines. They are used for precise guidance of tool components to ensure accurate and repeatable punching processes.

These guide bushes are made from high-quality case- hardening steel. Case-hardening steel offers the requisite robustness and durability required for the high demands in tool technology. The bores of the punch guide bushes are rounded at one end, which facilitates the entry and exit of the punch and increases the service life of the bush. This curvature also helps to reduce friction and wear during operation. |

The DIN standard specifies the use of case- hardening steel for the manufacture of guide bushes. It specifies that the bushes must be hardened and ground to ensure a smooth and precise surface, which is essential for the smooth guidance of punches. The hardness is usually specified in HV, e.g. 740 ±40 HV 10.

Drill bushes from norelem

When it comes to high-quality drill bushes, norelem is your reliable partner. Our drill bushes are not only synonymous with precision and durability, but also offer an impressive variety of designs tailored to your specific requirements. But why should you purchase your drill bushes from norelem?

Our drill bushes are manufactured from high-quality materials such as free-cutting steel and case-hardening steel. These ensure an exceptional service life and consistent performance, even with intensive use. At norelem you will find a wide range of drill bushes covering all standard diameters and designs.

Our drill bushes are designed to meet DIN standards so that they can be easily integrated into existing systems. Replacing bushes is also straightforward, making your production processes smooth and efficient.