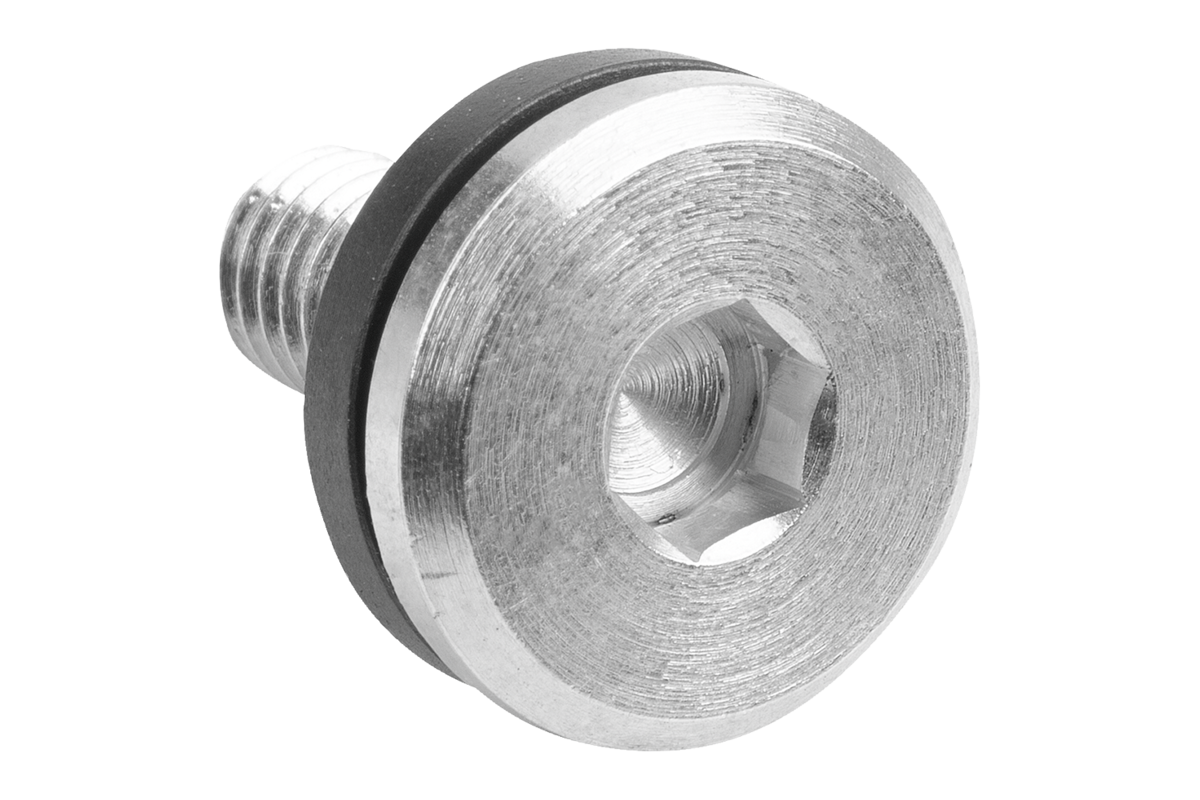

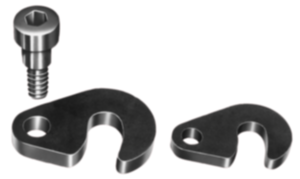

{"product":{"productId":"agid.24896","price":8.96,"name":"Steel flat head screw with tolerance compensation for floating joint, with external thread"},"currency":"EUR"}

- Floating bearing mountings with standard elements

- Compensates for temperature fluctuations

- Compensate for manufacturing tolerances

Description

Product description

The floating joint unit is a bolt for connecting two components, that permits a desired movement of those components in relation to each other.

The floating joint unit is mainly used when:

- a temperature change alters the dimensions of a component

- assembly inaccuracies occur

- manufacturing tolerances must be compensated for

- the position of the components varies due to dynamic loads

The floating joint unit is mainly used when:

- a temperature change alters the dimensions of a component

- assembly inaccuracies occur

- manufacturing tolerances must be compensated for

- the position of the components varies due to dynamic loads

Material

Bolt steel.

Plain bearing high-performance bearing polymer.

O-ring NBR.

Plain bearing high-performance bearing polymer.

O-ring NBR.

Version

Bolt electro zinc-plated.

Note

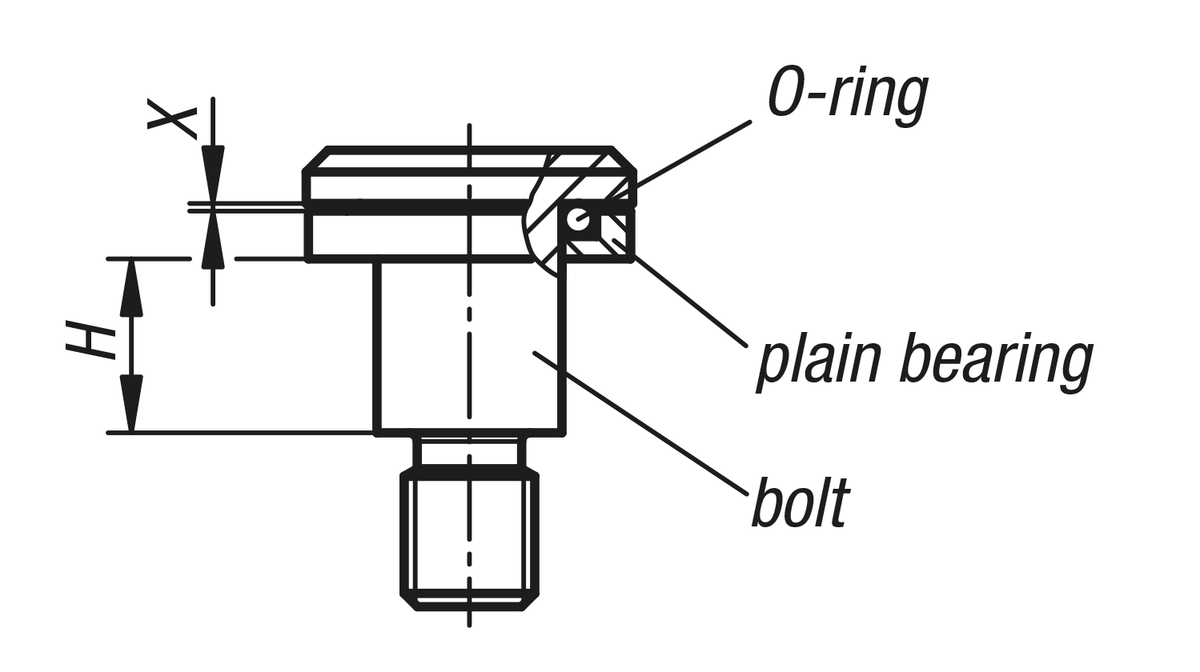

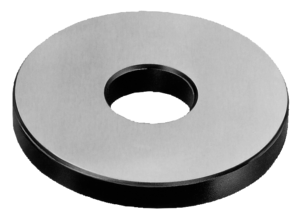

The floating joint unit consists of three components. Bolt, plain bearing and O-ring.

The plain bearing compresses the O-ring when the bolt is screwed into the hole. This occurs by max.the dimension X. The plain bearing will now be seated under the bolt head. The travel is accordingly limited by the installation dimension H +0.2. A floating support is thus always guaranteed.

The plain bearing compresses the O-ring when the bolt is screwed into the hole. This occurs by max.the dimension X. The plain bearing will now be seated under the bolt head. The travel is accordingly limited by the installation dimension H +0.2. A floating support is thus always guaranteed.

Temperature range

-20 °C to +80 °C.

Assembly

Note on the specified torque:

The torques refer to screwing into steel components. When installing in softer materials, the indentation (setting) of the shaft diameter D2 must be taken into account. A lower torque should be used here. Glue the bolt in place to prevent loosening with lower torques.

The torques refer to screwing into steel components. When installing in softer materials, the indentation (setting) of the shaft diameter D2 must be taken into account. A lower torque should be used here. Glue the bolt in place to prevent loosening with lower torques.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.