T-grips, wing grips

Manual securing and locking with wing grips

What are wing grips?

Advantage of wing grips

Versatility of grip types

The wing grips from norelem

Manual securing and locking with wing grips

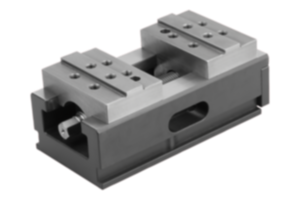

T-grips and wing grips belong to the product group of flexible standard parts. They are used in industrial and craft applications and are characterised by their ergonomic shape.

The shape enables an even distribution of force on the workpiece. This is particularly advantageous for work that requires high precision or vigorous tightening.

Some T-grips are also known as tommy bars, all have a shape that resembles the letter T. They are often used when a high level of leverage is required, for example when screwing in bolts or clamping operations.

The lever effect enables the user to exert more torque and to work more efficiently with less effort. T-grips are often found in sectors such as metal processing and the automotive industry.

Wing grips, sometimes called wing nuts, have two opposing wings. These enable the user to operate the device manually without additional tools.

Due to its shape, a wing grip is easy to grasp and turn with one hand. This is why they are often used in areas where quick and tool-free fastening is required. The easy handling makes them ideal for applications where frequent adjustments are necessary.

Are you considering using a wing grip or T-grip, but are still unsure which type of grip to choose?

What are wing grips?

Wing grips are special grips that are installed on tools, machines or fastening elements. Their shape, with two ‘wings’ protruding from the sides, enables easy handling. A wing grip offers more leverage and therefore makes manual tightening or loosening easier without the need for additional tools.

The grips are used on devices that require quick and tool-free adjustment. They are used in machine construction, furniture making and other technical fields.

A wing grip consists of two arms or wings that project from the sides, a grip body and a threaded pin or tapped hole/bush.

The wings are the protruding parts that give the grip its name. They are attached to the side and have a flat, often rounded shape. They provide a good gripping surface for applying sufficient manual torque.

The grip body is the central part of the grip that connects the wings. Depending on the model, it can be cylindrical or conical. The grip body may have an internal thread or opening to engage a shaft or screw.

Many wing grips have a threaded pin or insert. These may be made of metal or plastic and are used to attach the grip to a component. The thread enables tightening or loosening, similar to a conventional screw.

Advantage of wing grips

Wing grips offer numerous advantages in a range of different areas.

One of the biggest advantages is user-friendliness. The wide wings enable optimal power transmission. The shape of the grip facilitates the operation of tools, machines or doors, without the need for excessive force. The ergonomic design also ensures better handling. The grip is easy to grasp and turn, even when wearing gloves.

Another advantage is versatility. These standard parts are used in many different industries, from the automotive industry to mechanical engineering and medical technology. Due to their simple construction, they are also very robust and durable, which keeps maintenance costs low.

The variety of grips also includes different versions. Wing grips are available in a range of materials and sizes, so they can be adapted to suit individual requirements.

The grips are made of materials such as stainless steel, polyamide and thermoplastic.

Stainless steel grips are particularly resistant to rust and corrosion. This makes them ideal for use in humid or chemically aggressive environments. The material offers high mechanical strength and durability. This makes a stainless steel grip suitable for applications with high pressure and load.

Polyamide, on the other hand, is a lightweight material, which makes the grips easier to handle. It has good mechanical properties and is resistant to impact and wear. Polyamide wing grips have a degree of resistance to many chemicals, making them suitable for various industrial applications.

Thermoplastic wing grips offer high resistance to shocks and mechanical loads. As the material is electrically insulating, these grips are suitable for applications in electrical engineering.

Each of these materials boasts specific advantages that benefit wing grips in various applications. The choice of material depends heavily on the specific requirements of the respective application.

Wing grips are therefore not only a practical solution, but also a flexible and cost-effective one for a range of applications.

Versatility of grip types

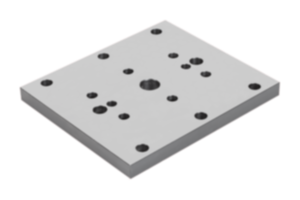

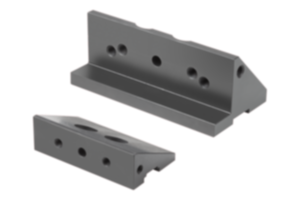

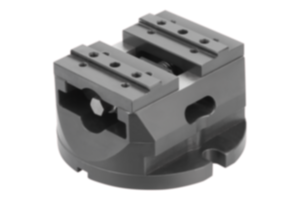

In addition to wing grips and T-grips, the norelem range also includes the following products:

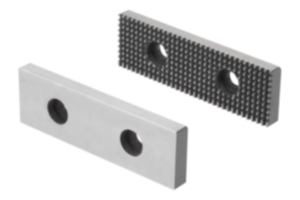

- Wing nuts: Wing nuts made from 1.4404 stainless steel enable simple and tool-free screw connections. They can be effortlessly tightened and loosened again. The nuts are polished all over and have a surface finish (Ra) of 0.8 µm. This helps prevent dirt and residues from adhering and ensures easy cleaning. On request, these fittings are also available with inch threads or external threads.

- Grip nuts: Grip nuts have an ergonomic shape and enable manual assembly and disassembly without tools. They are made of thermoplastic, a robust and durable plastic that offers a good grasp. The bush, i.e. the internal thread of the grip nut, can be made of various materials: steel, stainless steel or brass. The steel bush is blue passivated to prevent corrosion. Bushes made of stainless steel and brass, on the other hand, are untreated (bright) because they are naturally highly corrosion resistant.

- Grip screws: Grip screws have an ergonomic head that enables manual tightening and loosening without tools. The screw grips are made of black thermoplastic. The threaded pin that forms the actual screw thread is made of steel or stainless steel. Here, too, the steel threaded pin is blue passivated, while the stainless steel pin is untreated (bright).

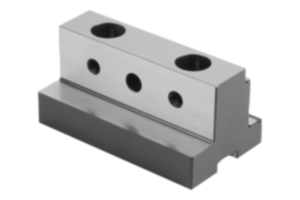

- Bar knobs: Claw nuts are used in the machine construction and automotive industries. They are made of malleable cast iron, a material known for its high strength and toughness. These properties make bar knobs particularly robust and durable. Our type of bar knobs are sand-blasted, which results in a rough surface finish. This texture improves hold and ensures a secure joint with other components.

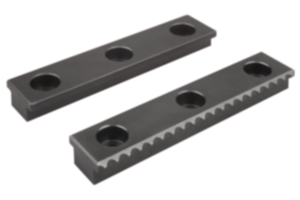

- Tommy bars: Tommy bars are operating elements that are used in a variety of applications to enable easy handling and quick assembly. They are available in two versions, with a fixed or sliding T-bar. Both meet the standards DIN 6305 and DIN 6307. Both tommy bar types are made from high-quality steel and black oxidised to ensure corrosion resistance.

- T-thrust screws: T-thrust screws are special fastening elements. They are characterised by their distinctive T-bars, which enable easy handling. They are made of steel, are black oxidised and have a hardened thrust point. Two types are available: T-thrust screws with a sliding T-bar and with a fixed T-bar. By the sliding version, the T-bar can be moved, whereby a spring holds it in any position. A collar on each end of the bar limits the sliding movement and stops the bar falling out. By the fixed version, the T-bar is pressed in and cannot be moved.

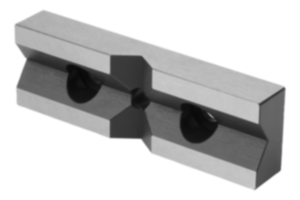

- Lock grips: These versatile locking and fastening elements are made from 1.4308 stainless steel or steel. They are available in either bright stainless steel or black oxidised steel. Thanks to their ergonomic design with a recessed grip, they provide a secure hold and enable the transmission of high clamping forces. The lateral centring also permits various fastening methods, allowing the grip to be flexibly adapted to different requirements.

The wing grips from norelem

The wing grips from norelem offer a combination of quality, functionality and versatility. This makes these standard parts an ideal choice for industrial applications. norelem stands for robust, durable products made from high-quality materials such as thermoplastic and stainless steel.

Our standard and operating parts are optimally tailored to the needs of machine and plant construction and other industrial sectors. We enable customised solutions with a wide range of models, thread types and sizes.