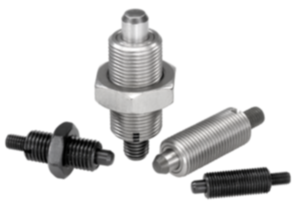

{"product":{"productId":"agid.16468","price":19.4,"name":"Premium - Indexing plungers, steel or stainless steel with plastic mushroom grip, tapered indexing pin and locknut"},"currency":"EUR"}

- Higher processing requirements

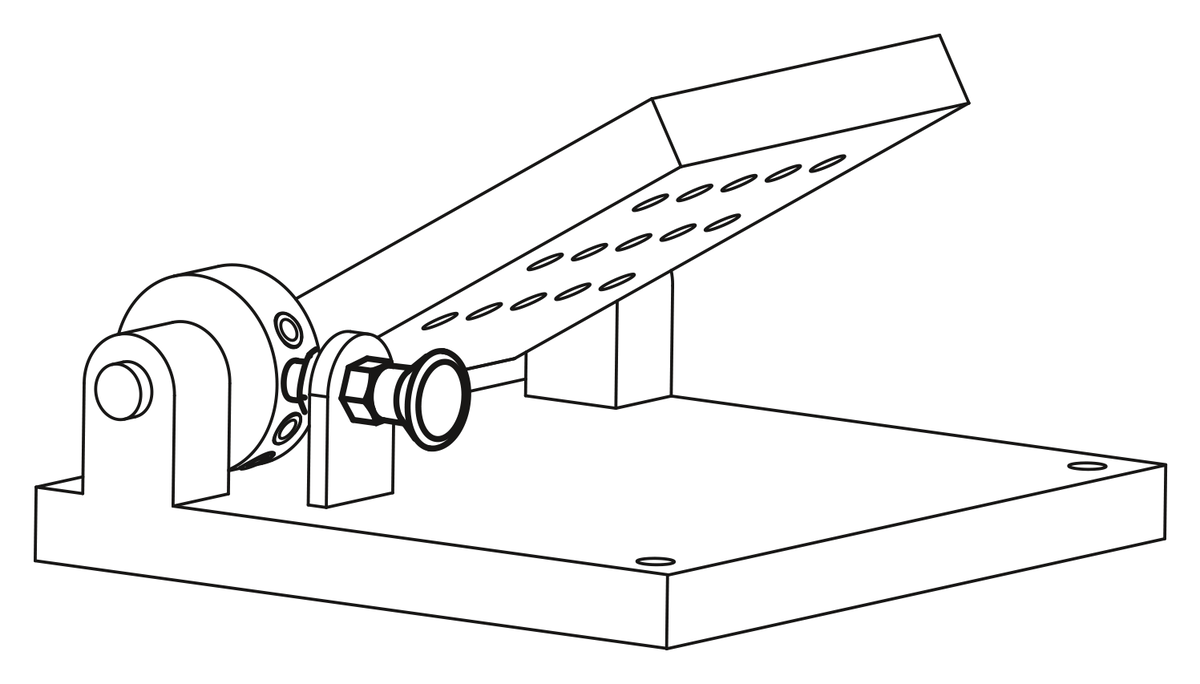

- Indexing plungers facilitate indexing and locking

- Application sectors: machine, instrument and fixture construction, measuring technology, domestic use

- High stability

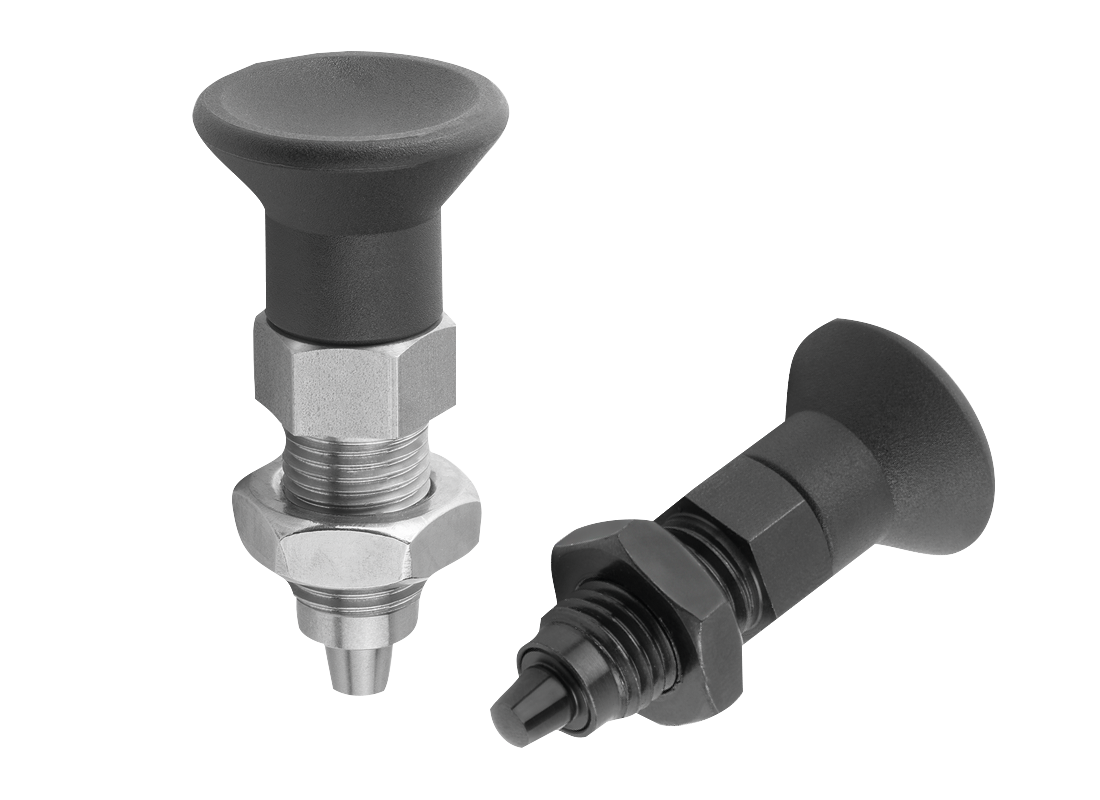

- Material: steel or stainless steel

Description

Product description

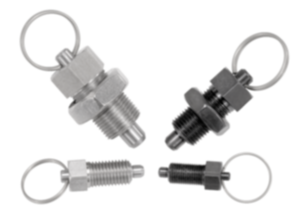

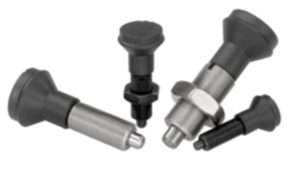

Indexing plungers are used where any change in locking position due to lateral forces should be prevented. A new indexed position can be only be moved to after the pin has been manually retracted. Form D is recommended for applications where the indexing pin should remain disengaged for an extended period and be prevented from springing back.

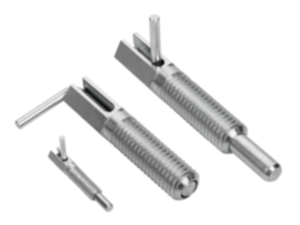

Premium indexing plungers are characterised by higher manufacturing demands of the indexing plunger and the threaded sleeve. In addition, a centring locator has been added to the threaded sleeve, which can be used to increase positioning accuracy.

Premium indexing plungers are characterised by higher manufacturing demands of the indexing plunger and the threaded sleeve. In addition, a centring locator has been added to the threaded sleeve, which can be used to increase positioning accuracy.

Material

Steel version:

Threaded sleeve and indexing pin free-cutting steel.

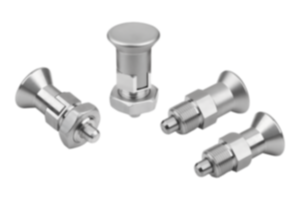

Stainless steel version:

Threaded sleeve 1.4305.

Indexing pin 1.4034.

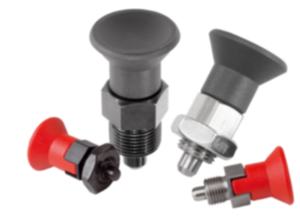

Mushroom grip thermoplastic.

Version

Steel version:

Threaded sleeve black oxidised.

Indexing pin hardened, ground and black oxidised.

Stainless steel version:

Threaded sleeve bright.

Indexing pin hardened and ground, bright.

Mushroom grip black grey RAL7021.

Threaded sleeve black oxidised.

Indexing pin hardened, ground and black oxidised.

Stainless steel version:

Threaded sleeve bright.

Indexing pin hardened and ground, bright.

Mushroom grip black grey RAL7021.

Assembly

When using the threaded sleeve centring, it is recommended the receiving reamed hole be machined before tapping.

The conical contact surface is aligned by the threaded sleeve and locking nut.

The conical contact surface is aligned by the threaded sleeve and locking nut.

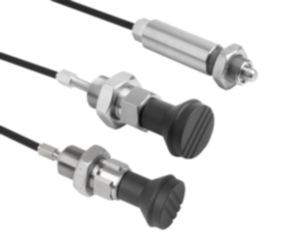

On request

Special versions.

Accessory

Matching tapered bush 03089.

Important note on downloading CAD models

In order to download our CAD models, you must log in first. If you have not created an account yet, please register under "My Account" (right side of the screen) and follow the instructions.